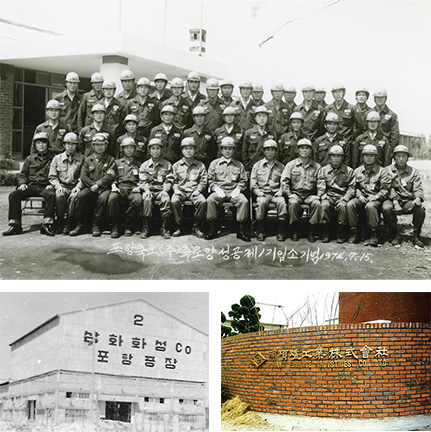

POSCO FUTURE M has the longest history within POSCO Group. In 1963, originally named Samhwa Hwasung Co., Ltd., POSCO FUTURE M started as an alkaline refractories producer. In 1994, by merging with Pohang Furnace, an industrial furnace maintenance and construction company, the company transformed into a furnace materials supplier with integrated service offerings, ranging from refractories manufacturing to furnace installation.

After launching a quicklime business to supply the iron and steelmaking material to Pohang and Gwangyang Steelworks, we have become Korea’s largest quicklime producer. Additionally, coke oven gas generated during ironmaking is recycled for our chemical business. Our product offerings include needle coke and pitch coke, essential materials for electric vehicle batteries and electric furnaces for steel industry.

We ventured into the anode active material (AAM) business in 2010, followed by the cathode active material (CAM) business in 2018, carving out a unique position as the only Korean business capable of offering both rechargeable battery components, CAM and AAM. Additionally, we have exclusive knowhow to manufacture artificial graphite from pitch coke, a steelmaking by-product. Finally, in collaboration with other affiliated subsidiaries specialized in lithium and nickel manufacturing, we are able to source requisite raw materials for CAM and AAM. Consequently, POSCO Group has ownership across the full value chain of the rechargeable battery materials business.

As the world’s largest CAM plant, our Gwangyang plant delivers 90,000 tons per year. By 2030, our goal is to expand annual production capacity to 1 million tons for CAM and 370,000 tons for AAM. By doing so, POSCO FUTURE M will be recognized as a global top-tier eco-friendly future materials provider.