- Home

- Business

- Battery Materials

Battery Materials

Rechargeable batteries function when lithium (Li) ions move between the cathode(+) and the anode(-). Because they can be recharged and used repeatedly, rechargeable batteries are embedded in mobility (EVs), IT devices and various home appliances.

A rechargeable battery consists of four components: cathode, anode, electrolyte and separator. Among the four, POSCO FUTURE M supplies to the world the most essential components, cathode and anode active materials.

We are unique in Korea as a supplier of both cathode and anode active materials. Building on our R&D expertise, we will ramp up capacity, complete a raw material value chain and develop next-generation materials. Our ultimate goal is to be a top-tier supplier in the global market.

Charging an electric car

Our main product is high-nickel NCM*, a common type of CAM found in EV batteries. By adding aluminum to the mix, we have developed NCMA to offer enhanced thermal stability. *nickel, cobalt and manganese

In response to the growing EV market, we plan to expand CAM production capacity.

-

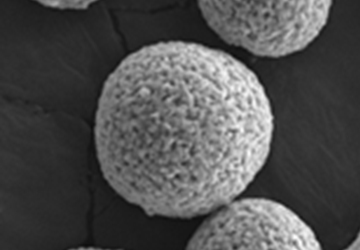

High-nickel cathodes

-

Cathodes Production Lines

| Product category | Characteristics | Applications | |

|---|---|---|---|

| Cathode Active Materials | NCM-6x |

- High-nickel cathode material comprised of nickel (60%), cobalt and manganese - Characterized by high capacity, high stability and minimum gas evolution reaction during charge and discharge |

electric cars (EV) |

| NCM-8x |

- High-nickel cathode material comprised of nickel (80%), cobalt and manganese - Characterized by high capacity, high thermal stability and low internal resistance |

mobile devices, e.g., smartphones, tablet pcs, laptops electric machines (power tool) |

|

| NCMA |

- High-nickel cathode material comprised of nickel (80%), cobalt, manganese and aluminum - Characterized by high capacity, low internal resistance and higher thermal stability |

electric cars electric machines (power tool) |

|

| NCA |

- High-nickel cathode material comprised of nickel (80%), cobalt, aluminum - Characterized by high capacity, low internal resistance and higher thermal stability |

electric cars electric machines (power tool) |

|

Given the impact of precursor composition to CAM price and parameters, we are conducting studies to identify the optimal mix. In addition, POSCO FUTURE M will continue to increase in-house production of precursors to ensure reliable supply of battery materials

-

Precursors

-

Precursor Production Lines

Gwangyang Cathode Material Plant

- Annual capacity : 90K tons

- (An additional 52.5K tons/year plant to be completed by 2025)

- Location : Yulchon Industrial Complex, Gwangyang

Pohang Cathode Material Plant

- Annual capacity : 60k tons

(phased expansion to 106K tons/year by 2025) - Location : Yeongilman Industrial Complex, Pohang

Tongxiang, China (ZPHE/ZHPE)

- Annual capacity : 25K tons of cathode

35K tons of precursor - Location : Tongxiang, Zhejiang Province, China

Quebec, Canada (Ultium CAM)

- Annual capacity : cathode(phased expansion to 30K tons/year and to 63K tons/year)

precursor(phased expansion to 45K tons/year) - Location : Bécancour, Quebec, Canada

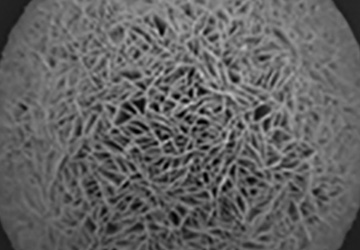

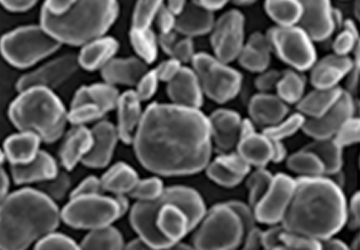

Our anode active material (AAM) offering includes natural graphite and low-expansion types. To add next-generation products to the portfolio, we are developing artificial graphite, silicon and lithium metal-type AAM.

Even after repeated charging and discharging, our high-performance AAM sustains form and stability.

-

Natural graphite Anodes

-

Anodes Production Lines

| Product category | Characteristics | Applications | |

|---|---|---|---|

| Anode Active Materials | Natural graphite anode materials |

- Made from natural graphite - Characterized by high conductivity, high energy density and longevity |

electric cars mobile devices, e.g., smartphones, tablet pcs, laptops electric machines (power tool) energy storage systems (ESS) |

| Artificial graphite anode materials |

- Made from coke - Characterized by high energy density and longevity owing to the application of particle shape control and surface treatment techniques. |

electric cars | |

(Natural graphite) Sejong Anode Material Plant No. 1

- Annual capacity : 26K tons (natural graphite)

- Location : Jeon-ui Regular Industrial Complex, Sejong

(Natural graphite)Sejong Anode Material Plant No.2

- Annual capacity : 48K tons (natural graphite)

- Location : High-Tech Industrial Complex, Sejong

Pohang (Artificial) Anode Material Plant

- Annual capacity : 8K tons (13K tons to be added)

- Location : Blue Valley National Industrial Complex, Pohang

| Category | Product | Description | |

|---|---|---|---|

| Cathode Materials | Low Cost | Manganese Rich (LMR) |

- Reduces proportion of nickel and cobalt while increasing manganese to enhance price competitiveness and stability - When recycling is considered, price is similar to LFP but enables up to 30% higher energy density |

| Lithium Manganese Iron Phosphate (LMFP) | - Adds manganese to LFP to maintain similar price level to LFP but with 15-20% higher energy density | ||

| Lithium Iron Phosphate (LFP) | - Uses lithium iron phosphate raw materials to offer high price competitiveness and stability, leading to recent increase in usage (for entry-level EVs/ESS applications) | ||

| Standard | High Voltage Mid-Nickel Single Crystal | - Despite lower nickel content (around 60%), maximizes energy density by increasing voltage (enabling longer driving range) | |

| Premium | Ultra High Nickel Single Crystal | - Premium product with over 95% nickel content in single-crystal form that maximizes electric vehicle driving range while enhancing stability | |

| Anode Materials | Natural Graphite | Fast-Charging Low-Expansion | - Improves performance of proprietary low-expansion natural graphite anode materials to reduce charging time by 30% compared to existing products |

| Artificial Graphite | High-Density Artificial Graphite | - Adds waste powder to anode materials to create denser particle structure, increasing capacity and reducing charging time by 15% compared to existing products | |

| Silicon | Silicon-Carbon Composite (Si-C) | - Offers approximately 5 times higher storage capacity than graphite-based anode materials, enabling extended electric vehicle driving range and fast charging | |